im making a board right now...

+13

mariajuana

dek

sub_zero

choiboards

awtkas983

wipeoutkid

carloboy

gax

Strange 1

filipinodriver

boynegro

sk8punk

teji101

17 posters

ALON :: The Community :: D.I.Y Section

Page 3 of 5

Page 3 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

2nd day!!!

2nd day!!!

ano bang plywood gngmit nyo? ok n ung marine.. nka bend n cya...hintayin ko nlng tlga 2muyo ng maayos.. and then nxt??? db maglalagay n ng masilya? help ulit s info!! salamat!!!

sub_zero- Skimboarder

- Posts : 320

Join date : 2008-07-12

Age : 39

Location : manila

Re: im making a board right now...

Re: im making a board right now...

Sir try mo to baka sakaling makatulong, https://www.youtube.com/results?search_query=how+to+make+skimboard&search_type=&aq=f mga videos on how to make your boards, though its in full detail, check mo na rin.

awtkas983- Hardcore Skimboarder

- Posts : 783

Join date : 2008-07-04

tnx!!!

tnx!!!

salamat awtkas!! n try ko nrin manood s youtube.. pro kumukuha p rin ako ng ibang infos.. slamat!! sna may magamit ako s skimtrip.. heheheh...

sub_zero- Skimboarder

- Posts : 320

Join date : 2008-07-12

Age : 39

Location : manila

Re: im making a board right now...

Re: im making a board right now...

lagyan mo ng masilya sa rails, ung gilid ng board mo. dun ung pinakamalakas magabsorb ng tubig. at yung surface syempre. tpos lagyan mo ng pinturang madaming layer. hehehe

pintura..

pintura..

anong pintura ginagamit? latex paint?balak ko nga taktakpan ko ng buong fiber ung wood.. aus lng kya un?tnx s info!!

sub_zero- Skimboarder

- Posts : 320

Join date : 2008-07-12

Age : 39

Location : manila

Re: im making a board right now...

Re: im making a board right now...

enamel gamitin mo. mas matibay yun kesa sa latex pag kahoy ung application. ok lang ung lagyan mo ng fiberglass. pero kung ganon, wag mo na lagyan ng masilya. mas matibay ang fiberglass sa masilya e.

re:

re:

sa tingin mo b aus na ung size n ginawa ko.?? 3ft x 2ft ung size n ginawa ko eh...120 lbs ako.. aus n kya ung w8 ko pra makaride dun?

sub_zero- Skimboarder

- Posts : 320

Join date : 2008-07-12

Age : 39

Location : manila

tanong lang mga master

tanong lang mga master

mga sir ano po ba ung fibergalss resin? un po ba ung parang glass pag inapply?

tsaka san po nakakabili nun dito sa manila? , kasi ang binibigay sakin parate sa

, kasi ang binibigay sakin parate sa

mga ace hardwares eh ung epoxy na may resin with hardener...

pano po ba ung procedure pag apply nun?

ang ginawa ko kasi eh nilagyan ko muna nung fiberglass tape (ung parang net)

tapos nilagyan ko na lng nun epoxy, kaso ang pangit nung natuyo eh, hindi pantay ang dameng bukol hehehe...

gawa sana ako uli ng bago eh sayang ung natirang marine ply hehe..

mga sir help naman..sensya na po ang daming tanong..

thanks... btw am new here in the forum..

tsaka san po nakakabili nun dito sa manila?

mga ace hardwares eh ung epoxy na may resin with hardener...

pano po ba ung procedure pag apply nun?

ang ginawa ko kasi eh nilagyan ko muna nung fiberglass tape (ung parang net)

tapos nilagyan ko na lng nun epoxy, kaso ang pangit nung natuyo eh, hindi pantay ang dameng bukol hehehe...

gawa sana ako uli ng bago eh sayang ung natirang marine ply hehe..

mga sir help naman..sensya na po ang daming tanong..

thanks... btw am new here in the forum..

dek...

dek...

welcome to alon dek!! san kb s manila?meron binibilhan dito s manila sa may bambang..iba ung epoxy resin sa poly resin..liquid un hindi cya putty... gumamit k ng liha or mga electric sander try mo bka kuminis un..madali lng un..dito rin ako nakakuha ng info..

sub_zero- Skimboarder

- Posts : 320

Join date : 2008-07-12

Age : 39

Location : manila

Re: im making a board right now...

Re: im making a board right now...

Search for polymer products. They sell the resin. They have a few shops around metro manila. The people there are helpful too. You can ask them how to work the resin.

Re: im making a board right now...

Re: im making a board right now...

dek wrote:mga sir ano po ba ung fibergalss resin? un po ba ung parang glass pag inapply?

tsaka san po nakakabili nun dito sa manila?, kasi ang binibigay sakin parate sa

mga ace hardwares eh ung epoxy na may resin with hardener...

pano po ba ung procedure pag apply nun?

ang ginawa ko kasi eh nilagyan ko muna nung fiberglass tape (ung parang net)

tapos nilagyan ko na lng nun epoxy, kaso ang pangit nung natuyo eh, hindi pantay ang dameng bukol hehehe...

gawa sana ako uli ng bago eh sayang ung natirang marine ply hehe..

mga sir help naman..sensya na po ang daming tanong..

thanks... btw am new here in the forum..

alam mo dek.. sa mga tanong mo malalaman mo ung mga sagot sa pag search lang sa google. hehehe. seryoso. dun ko nakuha ung mga tanong kong ganyan na tipo dati.

size...

size...

ano bang size mas pde s 130 lbs n tao??? medium db? pro gano kalaki un? pa reply nmn ung height and width nya.. salamat!!!

sub_zero- Skimboarder

- Posts : 320

Join date : 2008-07-12

Age : 39

Location : manila

tnx.

tnx.

salamat mga master....

try ko hanapin bukas ung store nung polymer products hehe,

mahal kaya yung mga materials??

try ko hanapin bukas ung store nung polymer products hehe,

mahal kaya yung mga materials??

making a board

making a board

mura lng bro, dito smen 120 lng per liter ung poly resin tpos 25 pesos ung hardener tpos 140 ung fiber cloth.. malamang dun s mga mbibilhan mo medyo mgkaparehas ung price.. binigyan lng kita ng idea... dpende n rin kung gano kdaming resin mauubos mo.. ingat lng s pag lagay nun cloth makati s balat un...

sub_zero- Skimboarder

- Posts : 320

Join date : 2008-07-12

Age : 39

Location : manila

making a board

making a board

ako nman magtatanong.. anong size b pde s 130 lbs ung weight??? medium db? gano kalaki un?i mean height, width nia?

sub_zero- Skimboarder

- Posts : 320

Join date : 2008-07-12

Age : 39

Location : manila

tnx.

tnx.

salamat sir.

eto sir ung nakita ko nung naghahanap ako ng size ng skimboards

110 - 155 M 48" x 20"

size sir yan ng victoria skimboard..

sir malapit lang ba un pinagbibilhan mo sa lrt bambang station,

left side or right side,or along lrt??

anong pangalan sir nung store?

eto sir ung nakita ko nung naghahanap ako ng size ng skimboards

110 - 155 M 48" x 20"

size sir yan ng victoria skimboard..

sir malapit lang ba un pinagbibilhan mo sa lrt bambang station,

left side or right side,or along lrt??

anong pangalan sir nung store?

bambang station..

bambang station..

oo malapit lng.. left side lng tol.. san b location mo? kung pupunta k sabihan mo ko pra samahan kita.. walking distance lng nman dito smen un eh...

sub_zero- Skimboarder

- Posts : 320

Join date : 2008-07-12

Age : 39

Location : manila

bambang station...

bambang station...

ayos.. mukhang magagawa ko na board ko hehe

anong pangalan sir nung shop? along lrt lang ba?

left side papuntang monumento or baclaran?

baka ako na lang sir siguro, nakakahiya naman sayo makakaabala pa ako

thankss..

anong pangalan sir nung shop? along lrt lang ba?

left side papuntang monumento or baclaran?

baka ako na lang sir siguro, nakakahiya naman sayo makakaabala pa ako

thankss..

.....

.....

d ko lam un pangalan ng store eh.. ppuntang north bound.. aus lng ... sbhan m ko para makita mo n rin.. hirap explain ung location eh..

sub_zero- Skimboarder

- Posts : 320

Join date : 2008-07-12

Age : 39

Location : manila

oo nga!!!

oo nga!!!

oo tol hinahanap kita ..tnxt kita ksao nka off fon mo...txt mo ko...09229779508.. papatulong sna ko..

sub_zero- Skimboarder

- Posts : 320

Join date : 2008-07-12

Age : 39

Location : manila

Re: im making a board right now...

Re: im making a board right now...

nagsearch po ako kung ano mas ok tlg kung epoxy resin o polyester resin eto ung nakalap kong infos

POLYESTER RESINS

Polyester resins are thermosetting; "thermosetting" means the plastic softens when initially heated, but sets permanently rigid once it has cooled (as opposed to "thermoplastics", which re-soften with heat).

Polyester resin is used for casting, auto body repair, wood filling, and as an adhesive. It has good wear and adhesive properties, and can be used to repair and bond together many different types of materials. Polyester resin has good longevity, fair UV resistance, and good resistance to water. It is important to recognize that all polyester resin products are not created equal; their chemical makeup is complex and can have a wide range of properties. As a filler in auto repair, for example, this material is formulated for superior adhesion to paints and metals, but cures very hard to resist surface trauma; it is therefore only marginally sandable. As a filler for millwork, however, polyester must be softer than the wood substrate so it can be sanded without leaving fills standing proud of surfaces.

EPOXY RESINS

Epoxies are sold in hardware stores, typically as a pack containing separate resin and hardener, which must be mixed immediately before use. They are also sold in boat shops as repair resins for marine applications. Epoxies typically are not used in the outer layer of a boat because they deteriorate by exposure to UV light. They are often used during boat repair and assembly, and then over-coated with conventional or two-part polyurethane paint or marine-varnishes that provide UV protection.

There are two main areas of marine use. Because of the better mechanical properties relative to the more common polyester resins, epoxies are used for commercial manufacture of components where a high strength/weight ratio is required. The second area is that their strength, gap filling properties and excellent adhesion to many materials including timber have created a boom in amateur building projects including aircraft and boats.

Normal gelcoat formulated for use with polyester resins and polyester resins does not adhere to epoxy surfaces, though epoxy adheres very well if applied to polyester resin surfaces. "Flocoat" that is normally used to coat the interior of polyester fibreglass yachts is also compatible with epoxies.

Polyester thermosets typically use a ratio of at least 10:1 of resin to hardener (or "catalyst"), while epoxy materials typically use a lower ratio of between 5:1 and 1:1. Epoxy materials tend to harden somewhat more gradually, while polyester materials tend to harden quickly.

POLYESTER RESIN and VINYLESTER RESIN VS EPOXY

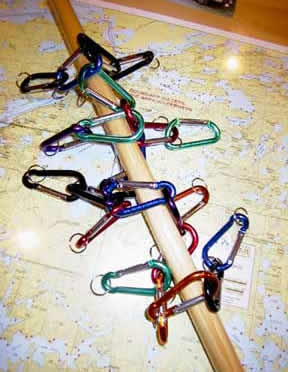

Vinylester resin forms a chain of molecules that kind of wrap themselves around a kevlar fiber. Now, I know that this is really perhaps oversimplified, but I am a simple man and definitely not a chemist. Using carabiners, the first photo on the left represents a strand of vinylester resin. Pretend that the paddle shaft is a kevlar fiber and the vinylester resin (carabiner chain) wraps around it in a fairly linear path. Those vinylester resin molecules follow each other in a chain formation and end up winding around the kevlar fibers as well. Sure, it's strong, but it doesn't make anywhere near as many contact binding points with the side of the very-nonporous, kevlar fibers as epoxy resin does.

Vinylester Resin around a kevlar fiber

(Actually a carabiner chain around a canoe paddle)

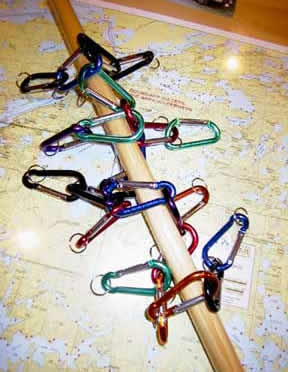

Epoxy resin around a kevlar fiber

(not nearly enough carabiners to do a great representation - but I think it works)

Crosslinking of Epoxy

The photo on the right represents the cross-linking that goes on with epoxy resin. The number of strands of molecules that link in from the sides of the kevlar fiber also link to each other and to other kevlar fibers fibers as well. The cross linking of molecules is virtually infinite and this results in a zillion contact points with each kevlar fiber in the canoe - and there are bazillions of those. Cross linking increases as the epoxy resin cures. In the photo above, I didn't have nearly enough carabiners (needed a bazillion) to make a really great representation of epoxy's molecular cross linking, but I think you can get the idea. The molecules of epoxy would actually link together to the fiber from all angles and directions. The number of links of epoxy molecules is to a kevlar fiber would be much harder to count than the number of links made by vinylester resin to a kevlar fiber.

The epoxy resin that Souris River Canoes uses is a very pure form of resin. It does not have the additives that are inside of the epoxy resins that us ordinary folks us can buy at the grocery store. Common epoxy has additives to allow mere mortals to use it at room temperature and actually have it cure while doing the cross-link thing. Even though the resin is still incredibly strong with additives that facilitate curing and allow us to apply it without heating it up, it is not as strong as the epoxy resin SR uses. Souris River's epoxy formula is close to solid at room temperature and uses a combination of two different hardeners. It has to be heated up just to get it out of the container.

The only way SR's blend of epoxy resin cures is through heating it in an oven. The oven curing process and the need for high room temperatures to make the resin runny enough to squeegee thru four layers of cloth, are two of the main reasons you do not see epoxy resin used in all of the various Brand X kevlar canoes out there today. Vinylester resin is just easier to use at the factory level but nowhere near as strong as epoxy resin. The cross linking is just not there in vinylester resin and the kevlar fibers can pull out of the glue more easily when stressed via paddling into a big rock or over a log. A heat-cured, epoxy resin, Souris River canoe, because of the nearly infinite number of cross-linked epoxy molecules making contact with every fiber in the canoe (plus each other due to the catalytic reaction that goes on), a Souris River Canoe essentially becomes one big honkin', continuous, plastic, molecule. Vinylester resin does not do this to the magnitude of epoxy resin and is therefore substantially weaker.

One final point - Heat-cured epoxy resin is used in the carbon fiber composite, V-22 Osprey and in Cirrus Aircraft. When it comes to flying, guess what? They don't use vinylester resin in any important parts like the wings, fuselage, etc. That says a lot to me. If it doesn't mean much to you, you haven't been paying attention to all this typing.

Thanks to Mike Daniels for 'splaining epoxy cross linking to me and subsequently, to you.

Even More Information

Here is some other technical data that I gleaned off of epoxy resin websites by Maas and West Systems. (If you think this is just a sales pitch, heck, you're sitting here looking at this web page on the internet - use Google and research it for yourself.) You may find it interesting regarding the differences between Epoxy Resin and Vinylester or Polyester Resins. In case you don't already know it, Souris River Canoes are all made with a very high grade epoxy resin. Pretty much everybody else in the canoe world uses either vinylester resin and some the weaker polyester resin.

In the marine industry, liquid plastics, namely epoxies, polyesters, and vinylesters are used to saturate (wet out) the fibers of wood, glass, kevlar amarid, or carbon to form a fiber reinforced plastic (FRP). To create a quality part, adhesion to the fibers is the most important factor. Not all resins keep their grip on fibers equally.

Epoxy resin is known in the marine industry for its incredible toughness and bonding strength. Quality epoxy resins stick to other materials with 2,000-p.s.i. vs. only 500-p.s.i. for vinylester resins and even less for polyesters. In areas that must be able to flex and strain WITH the fibers without micro-fracturing, epoxy resins offer much greater capability. Cured epoxy tends to be very resistant to moisture absorption. Epoxy resin will bond dissimilar or already-cured materials which makes repair work that is very reliable and strong. Epoxy actually bonds to all sorts of fibers very well and also offers excellent results in repair-ability when it is used to bond two different materials together. Initally, epoxy resin is much more difficult to work with and requires additional skill by the technicians who handle it.

Vinylester resins are stronger than polyester resins and cheaper than epoxy resins. Vinylester resins utilize a polyester resin type of cross-linking molecules in the bonding process. Vinylester is a hybrid form of polyester resin which has been toughened with epoxy molecules within the main moleculer structure. Vinyester resins offer better resistance to moisture absorption than polyester resins but it's downside is in the use of liquid styrene to thin it out (not good to breath that stuff) and its sensitivity to atmospheric moisture and temperature. Sometimes it won't cure if the atmospheric conditions are not right. It also has difficulty in bonding dissimilar and already-cured materials. It is not unusual for repair patches on vinylester resin canoes to delaminate or peel off. As vinylester resin ages, it becomes a different resin (due to it's continual curing as it ages) so new vinylester resin sometimes resists bonding to your older canoe, or will bond and then later peel off at a bad time. It is also known that vinylester resins bond very well to fiberglass, but offer a poor bond to kevlar and carbon fibers due to the nature of those two more exotic fibers. Due to the touchy nature of vinylester resin, careful surface preparation is necessary if reasonable adhesion is desired for any repair work.

Polyester resin is the cheapest resin available in the marine industry and offers the poorest adhesion, has the highest water absorption, highest shrinkage, and high VOC's. Polyester resin is only compatible with fiberglass fibers and is best suited to building things that are not weight sensitive. It is also not tough and fractures easily. Polyesters tend to end up with micro-cracks and are tough to re-bond and suffer from osmotic blistering when untreated by an epoxy resin barrier to water. This is really cheap stuff.

SOURCE:

http://www.redrockstore.com/resin.htm

http://en.wikipedia.org/wiki/Epoxy

http://en.wikipedia.org/wiki/Polyester_resin

POLYESTER RESINS

Polyester resins are thermosetting; "thermosetting" means the plastic softens when initially heated, but sets permanently rigid once it has cooled (as opposed to "thermoplastics", which re-soften with heat).

Polyester resin is used for casting, auto body repair, wood filling, and as an adhesive. It has good wear and adhesive properties, and can be used to repair and bond together many different types of materials. Polyester resin has good longevity, fair UV resistance, and good resistance to water. It is important to recognize that all polyester resin products are not created equal; their chemical makeup is complex and can have a wide range of properties. As a filler in auto repair, for example, this material is formulated for superior adhesion to paints and metals, but cures very hard to resist surface trauma; it is therefore only marginally sandable. As a filler for millwork, however, polyester must be softer than the wood substrate so it can be sanded without leaving fills standing proud of surfaces.

EPOXY RESINS

Epoxies are sold in hardware stores, typically as a pack containing separate resin and hardener, which must be mixed immediately before use. They are also sold in boat shops as repair resins for marine applications. Epoxies typically are not used in the outer layer of a boat because they deteriorate by exposure to UV light. They are often used during boat repair and assembly, and then over-coated with conventional or two-part polyurethane paint or marine-varnishes that provide UV protection.

There are two main areas of marine use. Because of the better mechanical properties relative to the more common polyester resins, epoxies are used for commercial manufacture of components where a high strength/weight ratio is required. The second area is that their strength, gap filling properties and excellent adhesion to many materials including timber have created a boom in amateur building projects including aircraft and boats.

Normal gelcoat formulated for use with polyester resins and polyester resins does not adhere to epoxy surfaces, though epoxy adheres very well if applied to polyester resin surfaces. "Flocoat" that is normally used to coat the interior of polyester fibreglass yachts is also compatible with epoxies.

Polyester thermosets typically use a ratio of at least 10:1 of resin to hardener (or "catalyst"), while epoxy materials typically use a lower ratio of between 5:1 and 1:1. Epoxy materials tend to harden somewhat more gradually, while polyester materials tend to harden quickly.

POLYESTER RESIN and VINYLESTER RESIN VS EPOXY

Vinylester resin forms a chain of molecules that kind of wrap themselves around a kevlar fiber. Now, I know that this is really perhaps oversimplified, but I am a simple man and definitely not a chemist. Using carabiners, the first photo on the left represents a strand of vinylester resin. Pretend that the paddle shaft is a kevlar fiber and the vinylester resin (carabiner chain) wraps around it in a fairly linear path. Those vinylester resin molecules follow each other in a chain formation and end up winding around the kevlar fibers as well. Sure, it's strong, but it doesn't make anywhere near as many contact binding points with the side of the very-nonporous, kevlar fibers as epoxy resin does.

Vinylester Resin around a kevlar fiber

(Actually a carabiner chain around a canoe paddle)

Epoxy resin around a kevlar fiber

(not nearly enough carabiners to do a great representation - but I think it works)

Crosslinking of Epoxy

The photo on the right represents the cross-linking that goes on with epoxy resin. The number of strands of molecules that link in from the sides of the kevlar fiber also link to each other and to other kevlar fibers fibers as well. The cross linking of molecules is virtually infinite and this results in a zillion contact points with each kevlar fiber in the canoe - and there are bazillions of those. Cross linking increases as the epoxy resin cures. In the photo above, I didn't have nearly enough carabiners (needed a bazillion) to make a really great representation of epoxy's molecular cross linking, but I think you can get the idea. The molecules of epoxy would actually link together to the fiber from all angles and directions. The number of links of epoxy molecules is to a kevlar fiber would be much harder to count than the number of links made by vinylester resin to a kevlar fiber.

The epoxy resin that Souris River Canoes uses is a very pure form of resin. It does not have the additives that are inside of the epoxy resins that us ordinary folks us can buy at the grocery store. Common epoxy has additives to allow mere mortals to use it at room temperature and actually have it cure while doing the cross-link thing. Even though the resin is still incredibly strong with additives that facilitate curing and allow us to apply it without heating it up, it is not as strong as the epoxy resin SR uses. Souris River's epoxy formula is close to solid at room temperature and uses a combination of two different hardeners. It has to be heated up just to get it out of the container.

The only way SR's blend of epoxy resin cures is through heating it in an oven. The oven curing process and the need for high room temperatures to make the resin runny enough to squeegee thru four layers of cloth, are two of the main reasons you do not see epoxy resin used in all of the various Brand X kevlar canoes out there today. Vinylester resin is just easier to use at the factory level but nowhere near as strong as epoxy resin. The cross linking is just not there in vinylester resin and the kevlar fibers can pull out of the glue more easily when stressed via paddling into a big rock or over a log. A heat-cured, epoxy resin, Souris River canoe, because of the nearly infinite number of cross-linked epoxy molecules making contact with every fiber in the canoe (plus each other due to the catalytic reaction that goes on), a Souris River Canoe essentially becomes one big honkin', continuous, plastic, molecule. Vinylester resin does not do this to the magnitude of epoxy resin and is therefore substantially weaker.

One final point - Heat-cured epoxy resin is used in the carbon fiber composite, V-22 Osprey and in Cirrus Aircraft. When it comes to flying, guess what? They don't use vinylester resin in any important parts like the wings, fuselage, etc. That says a lot to me. If it doesn't mean much to you, you haven't been paying attention to all this typing.

Thanks to Mike Daniels for 'splaining epoxy cross linking to me and subsequently, to you.

Even More Information

Here is some other technical data that I gleaned off of epoxy resin websites by Maas and West Systems. (If you think this is just a sales pitch, heck, you're sitting here looking at this web page on the internet - use Google and research it for yourself.) You may find it interesting regarding the differences between Epoxy Resin and Vinylester or Polyester Resins. In case you don't already know it, Souris River Canoes are all made with a very high grade epoxy resin. Pretty much everybody else in the canoe world uses either vinylester resin and some the weaker polyester resin.

In the marine industry, liquid plastics, namely epoxies, polyesters, and vinylesters are used to saturate (wet out) the fibers of wood, glass, kevlar amarid, or carbon to form a fiber reinforced plastic (FRP). To create a quality part, adhesion to the fibers is the most important factor. Not all resins keep their grip on fibers equally.

Epoxy resin is known in the marine industry for its incredible toughness and bonding strength. Quality epoxy resins stick to other materials with 2,000-p.s.i. vs. only 500-p.s.i. for vinylester resins and even less for polyesters. In areas that must be able to flex and strain WITH the fibers without micro-fracturing, epoxy resins offer much greater capability. Cured epoxy tends to be very resistant to moisture absorption. Epoxy resin will bond dissimilar or already-cured materials which makes repair work that is very reliable and strong. Epoxy actually bonds to all sorts of fibers very well and also offers excellent results in repair-ability when it is used to bond two different materials together. Initally, epoxy resin is much more difficult to work with and requires additional skill by the technicians who handle it.

Vinylester resins are stronger than polyester resins and cheaper than epoxy resins. Vinylester resins utilize a polyester resin type of cross-linking molecules in the bonding process. Vinylester is a hybrid form of polyester resin which has been toughened with epoxy molecules within the main moleculer structure. Vinyester resins offer better resistance to moisture absorption than polyester resins but it's downside is in the use of liquid styrene to thin it out (not good to breath that stuff) and its sensitivity to atmospheric moisture and temperature. Sometimes it won't cure if the atmospheric conditions are not right. It also has difficulty in bonding dissimilar and already-cured materials. It is not unusual for repair patches on vinylester resin canoes to delaminate or peel off. As vinylester resin ages, it becomes a different resin (due to it's continual curing as it ages) so new vinylester resin sometimes resists bonding to your older canoe, or will bond and then later peel off at a bad time. It is also known that vinylester resins bond very well to fiberglass, but offer a poor bond to kevlar and carbon fibers due to the nature of those two more exotic fibers. Due to the touchy nature of vinylester resin, careful surface preparation is necessary if reasonable adhesion is desired for any repair work.

Polyester resin is the cheapest resin available in the marine industry and offers the poorest adhesion, has the highest water absorption, highest shrinkage, and high VOC's. Polyester resin is only compatible with fiberglass fibers and is best suited to building things that are not weight sensitive. It is also not tough and fractures easily. Polyesters tend to end up with micro-cracks and are tough to re-bond and suffer from osmotic blistering when untreated by an epoxy resin barrier to water. This is really cheap stuff.

SOURCE:

http://www.redrockstore.com/resin.htm

http://en.wikipedia.org/wiki/Epoxy

http://en.wikipedia.org/wiki/Polyester_resin

Re: im making a board right now...

Re: im making a board right now...

sub_zero wrote:oo tol hinahanap kita ..tnxt kita ksao nka off fon mo...txt mo ko...09229779508.. papatulong sna ko..

kaso wala akong load e. hehehe. cge save ko yan. tungkol saan ung maitutulong ko?

Re: im making a board right now...

Re: im making a board right now...

teji101 wrote:dek wrote:mga sir ano po ba ung fibergalss resin? un po ba ung parang glass pag inapply?

tsaka san po nakakabili nun dito sa manila?, kasi ang binibigay sakin parate sa

mga ace hardwares eh ung epoxy na may resin with hardener...

pano po ba ung procedure pag apply nun?

ang ginawa ko kasi eh nilagyan ko muna nung fiberglass tape (ung parang net)

tapos nilagyan ko na lng nun epoxy, kaso ang pangit nung natuyo eh, hindi pantay ang dameng bukol hehehe...

gawa sana ako uli ng bago eh sayang ung natirang marine ply hehe..

mga sir help naman..sensya na po ang daming tanong..

thanks... btw am new here in the forum..

alam mo dek.. sa mga tanong mo malalaman mo ung mga sagot sa pag search lang sa google. hehehe. seryoso. dun ko nakuha ung mga tanong kong ganyan na tipo dati.

thats true. everything is on the net. common now.

skimguapo- Skimboarder

- Posts : 380

Join date : 2008-07-22

Location : cavite

Re: im making a board right now...

Re: im making a board right now...

Yehey! Patapos na yung board na ginagawa ko. Pintura na lang kulang. Nakabili na din ako ng pintura kagabi. Bukas ko siguro pipintahan.

48x20x1/2 marine ply with marine epoxy coating. Tapos, yung bottom dinikitan ko ng formica. Sa long weekend ko ma-ttry kung maayos yung board. Sana maganda siya tapakan!

48x20x1/2 marine ply with marine epoxy coating. Tapos, yung bottom dinikitan ko ng formica. Sa long weekend ko ma-ttry kung maayos yung board. Sana maganda siya tapakan!

stikfan- Member

- Posts : 35

Join date : 2008-07-22

Page 3 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Similar topics

Similar topics» What you need to know in making your own board

» what's your board?

» Polymer Product Skimboard Making Seminar

» FOAMiE SKIM BOARD IN NEED... PLS HELP ... tnx \m/

» BOARD 4 SALE!!!!!!!

» what's your board?

» Polymer Product Skimboard Making Seminar

» FOAMiE SKIM BOARD IN NEED... PLS HELP ... tnx \m/

» BOARD 4 SALE!!!!!!!

ALON :: The Community :: D.I.Y Section

Page 3 of 5

Permissions in this forum:

You cannot reply to topics in this forum